PLC Monitoring

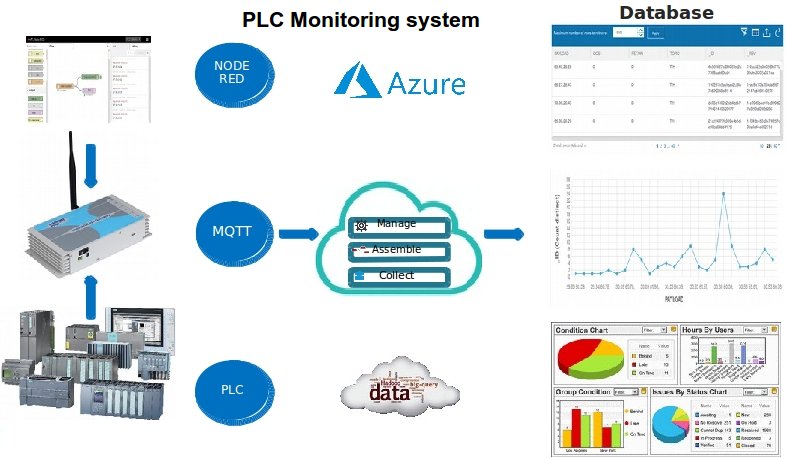

CASCADEMIC’s PLC Monitoring solution is an Industry 4.0 Solution. The Industry Standard system uses the existing PLC Infrastructure to tap the data from the Programmable Logic Controller (PLC) and communicates to the Cloud Platform, enabling predictive maintenance in remote areas.

The Solution has the provision of communicating to the PLC through Profibus, RS485 MODBUS or MODBUS TCP over Ethernet. Data is sent to the cloud through 3G/4G connectivity and the Solution is integrated with most cloud platforms enabling data visualization and analytics.

The PLC Monitoring Solution offers a rugged design with industrial grade components to ensure superior performance in any environment.

The Solution is based on NXP Semiconductors Chipset.

• Plug and Play architecture

• Non-intrusive retrofit solution

• Data sent to cloud platform over 3G, 4G

• Dashboards for real-time monitoring and control

• Data Concentrator for Sensor Nodes

• Ultra low power consumption

Traditionally, Industries have always depended on proprietary computer systems and sensors to monitor equipment and operations. But with Industry 4.0, these systems and sensors are more interconnected and rely on automated industrial processes.

CASCADEMIC's PLC Monitoring solution is perfectly suited for Process Control and Industrial Automation applications.

The digital era being highly disruptive in the Industrial space, has shaken up the business models and the core business of many industries. Smart Machines continually share information about current stock levels, problems or faults, environment parameters in industries, change in orders and demand levels. The processes and the input output ports controlled by the Programmable Logic Controller(PLC) drive the complete supply chain and in turn the revenues of efficiency of the industries. CASCADEMIC's PLC Monitoring System is instrumental in providing real time analysis and the feedback which help in boosting efficiency and optimizing throughput times, capacity utilization and quality in development, production, marketing & purchasing.

Used to monitor PLC and Scada equipments in industries, the PLC Monitoring Solution provides real-time analysis and feedback which help in monitor and control of Operational Efficiency, current stock levels, problems or faults, environment parameters in industries, change in orders and demand levels and also helps in predictive maintenance of industrial assets.

The PLC Monitoring Solution finds many applications including:

• Vessel Monitoring and navigation control Applications

• Automatic Facilities Control (Fans, ACs, etc)

• Intelligent Lighting

and is successfully installed in Textile factories, Boilers, Dairy Industry, Tea factory, Power generation industries.

The picture below gives an example representation of the Real-time monitoring of Boilers and the Efficiency Analysis.

| Hardware | |

| Processor | 32-bit ARM Micro-controller |

| Onboard Memory | Flash Storage |

| Power Supply |

Input: 24 V DC 7.4V, 1000mAh Battery Back Up |

| Connectivity | 3G, 4G Connectivity |

| Communication Protocol | RS485 MODBUS, MODBUS TCP over Ethernet |

| User Configuration |

Through UART, SMS and Server Polling Periodicity Server API |

| WiFi |

802.11b/g/n Client and Access Point Mode |

| Antenna | 3db External Wired Antenna |